News, events and interviews

The Bio-lexgen

There are many technical terms in our Bio-FlexGen project. And it’s even more confusing when they are not in your native language. Our consortium consists of 14 partners from 5 countries. Their mother tongues: Spanish, Swedish, Finnish, Hungarian, German.

It´s time for us to cover the most important words of the project in our Bio-FlexGen lexicon – the Bio-LexGen!

Combined heat and power plant (CHP)

You can do both? A combined heat and power plant (CHP) is a facility that produces both heat and electricity from a single energy source at high efficiencies. Such as our Bio-FlexGen Biomass-fired Top Cycle CHP plant: Compared to the traditional CHP technology, it produces renewable energy at double the efficiency. It does this by gasifying biomass with a high-pressure gas turbine process and massive steam injection.

Biomass

Being circular! What is biomass? Organic material from plants and animals that can be used to produce clean energy. Guess what our Biomass-fired Top Cycle plant runs on? Biomass from forestry and agriculture waste. So, yes, we are – naturally – part of a circular economy.

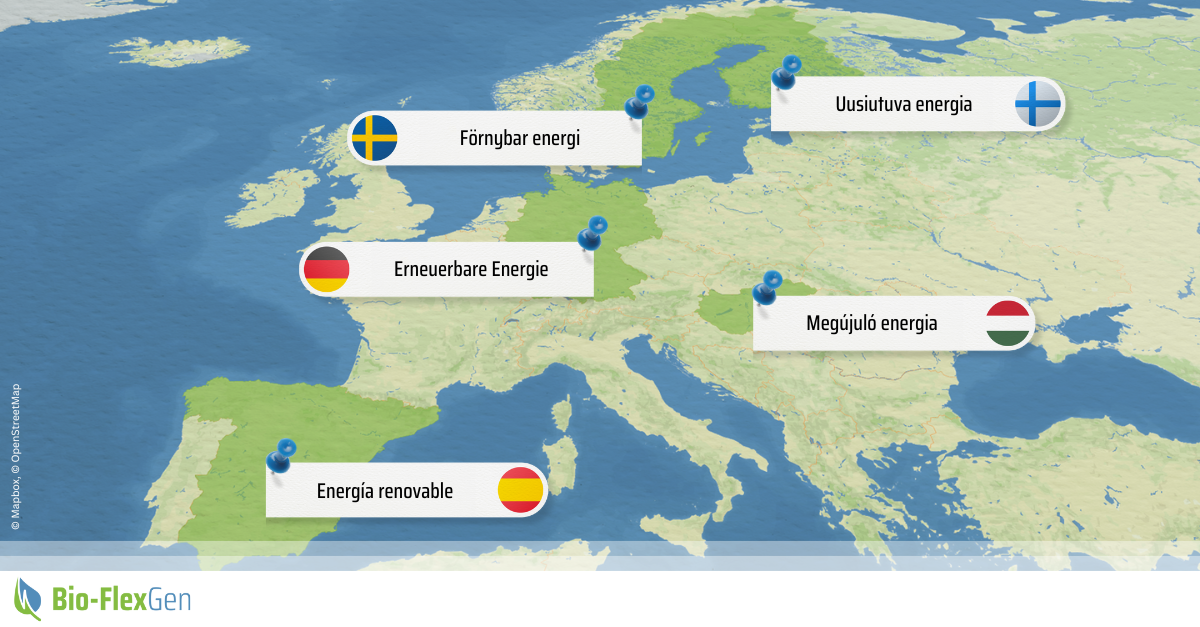

Renewable energy

Mother Earth has so much to offer. Renewable energy is produced from natural resources: Sunlight, wind, geothermal heat, or the movement of water. Our Biomass-fired Top Cycle plant runs on renewable fuels: Biomass or green hydrogen. So, we are part of the circular economy. Mother Earth will certainly approve!

Gasification

The core of our technology Gasification is a process that converts biomass into gas to produce energy. In our Biomass-fired Top Cycle plant, we will convert biomass to gas by heating it up to 900 °C, together with steam and compressed air. The gasified biomass is combusted with air at high temperatures. It drives a gas turbine which produces electricity. By the way: At nearly double the efficiency as standard combined heat and power plants! Yes, we score with our core!

Hydrogen

Hydrogen is a star! Hydrogen is the most abundant element in the universe that can be used to produce clean energy. Our Biomass-fired Top Cycle plant can produce hydrogen from biomass. It also runs on green hydrogen for fast energy dispatch. This flexibility is crucial for the energy transition in Europe. We are definitely starstruck!

Combustion

Boom! Combustion is a basic chemical process in which a substance reacts with oxygen and releases heat. We atBio-FlexGen will combust air with gasified biomass at 1.400 °Celsius. This happens in the Biomass-fired Top Cycle gas turbine. Due to the high temperatures, the turbine gets a lot of power and produces sustainable energy at a very high efficiency.

Syngas

Time to mix! Syngas is short for synthetic gas and describes a mixture of hydrogen (H), carbon monoxide (CO), and other gases. We at Bio-FlexGen will produce syngas from biomass. It is mainly waste from the Swedish forest industry. If we wouldn´t use it, it would be thrown away. So: Perfect circular economy! We are heating up the biomass to 900°C in a pressurise d reactor. This gas is then cooled and filtered, making it ready for combustion.

Energy efficiency

Making more from less! Everyone talks about energy efficiency, but what does it really imply? It´s all about minimising the waste of energy and improving the overall energy. Sounds easy, but the European (and global) industry has still a long way to go. We at Bio-Flexgen have developed a very smart solution: We will combine gasified fuel and a gas turbine. Thus, our Biomass-fired Top Cycle plant produces energy at unprecedented efficiencies. Fascinating, isn´t it?

Decarbonisation

Bye, bye, CO2! Decarbonisation means reducing or removing the emission of carbon dioxide (CO2) in the atmosphere. We at Bio-FlexGen will decarbonise the energy system. We will do this by increasing the flexibility and efficiency of combined heat and power plants. A 25 MW plant can save 90.000 tons of CO2 per year

Energy Transition

Getting there! Energy transition – big words, even bigger implications: It means a fundamental change in the energy sector. A shift from fossil-based energy production to renewable energy sources. And nothing less! With our innovative and flexible Biomass-fired Top Cycle (BTC) plant, we will accelerate this fundamental transition. The BTC can run on both green hydrogen and biomass.

Flexibility

“The measure of intelligence is the ability to change”. We at Bio-FlexGen took Einstein´s quote very seriously. That´s why we changed the standard combined heat and power plant approach - and took a turn on flexibility: Our Biomass-fired Top Cycle plant has three flexible operation modes: 1. Produces electricity and heat from biomass, 2. Produces green hydrogen from biomass, 3. Produces electricity and heat from hydrogen. Depending on the energy demands, we can switch between those modes hourly, daily and seasonally.

Sustainability

Thinking about the future! Lots of talking about sustainability these days. What does it mean per definition? Meeting the needs of the present generation without compromising future generations. That’s why our Biomass-fired Top Cycle plant relies on renewable, sustainable resources, such as biomass.

Carbon Capture and Storage

Negative is positive? Carbon capture and storage – the CO2 from the combustion in our Biomass-fired Top Cycle (BTC) plant can be captured and stored. A permanent storage could be, for example, a deep sea bed. This will make our BTC plant carbon negative! As biopower is already climate neutral, the additional storing of CO² will effectively remove carbon from the atmosphere. This kind of plant is also called Bioenergy Carbon Capture and Storage (BECCS) plant.