Solutions

Scientific community

Key message

Bio-FlexGen: A novel CHP plant (system) with hourly, daily and seasonal flexibility for a modern grid based on :

- H2 production from biomass and the flexibility to switch from CHP mode in the winter season to H2 production mode when needed.

- Abundant O2 from electrolysis for the biomass gasification system for H2 production, achieving highly-efficient integration of solar and wind energy in the system.

The Bio-FlexGen challenges:

Renewable energies from solar and wind fluctuate with the weather. Thus, there are major challenges for combined heat and power plants from renewables:

Scalable CHP solutions are needed to provide:

1) Security of supply

2.) Cost-effective plants and affordable energy

3.) Flexible and robust energy for the total energy mix

The Bio-FlexGen solutions:

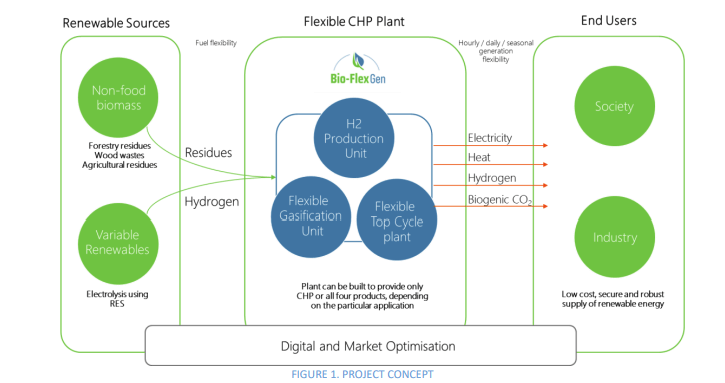

The Bio-FlexGen project will develop a flexible and highly efficient renewable energy CHP technology with 25 MW capacity. This plant, with on-demand digital optimisation, can flexibly generate four different products for the broader energy system or industrial applications: electricity, heat, hydrogen and/or CO2.

Biopower is provided with an extremely high efficiency (55%), plus a wide range (25%-100%) of loads. This is achieved by converting variable supplies of different low-cost biomass residues. Fast-dispatch peak power is provided off-season from renewable hydrogen. The plant can be designed to provide only CHP from biomass with fast-dispatch capability with hydrogen fuel. It can also be designed to provide all four products, depending on the particular application and its requirements.

The project will also look at how Bio-FlexGen can adapt to the energy system. This includes the economic viability of the CHP solution and the application of the technology for energy-extensive industry and the energy grid.

The overall concept is shown in the graph below. There are two main types of user cases: district heating and industry:

Combination of renewable energy sources:

1.Biomass

Bio-FlexGen will flexibly exploit the use of residual, non-food biomass. The gasification system is feedstock-flexible and scalable across various EU-applications. Moreover, it adjusts to biomass seasonal availability. Two types of biomass are targeted:

- a) Forest residues – including pellets, wood chips and forest residues. These prevail in northern and central EU countries.

- b) Wood waste – initial focus on low quality sorted wood waste. In the long run, Bio-FlexGen focuses on blends of agricultural residues. These are more abundant in southern Europe

2.Renewable hydrogen

The plant will use renewable hydrogen for combustion in a gas turbine during fast-response, hydrogen-firing mode. The hydrogen will be generated through electrolysis, driven with variable electricity from wind or solar energy.

The core of the project:

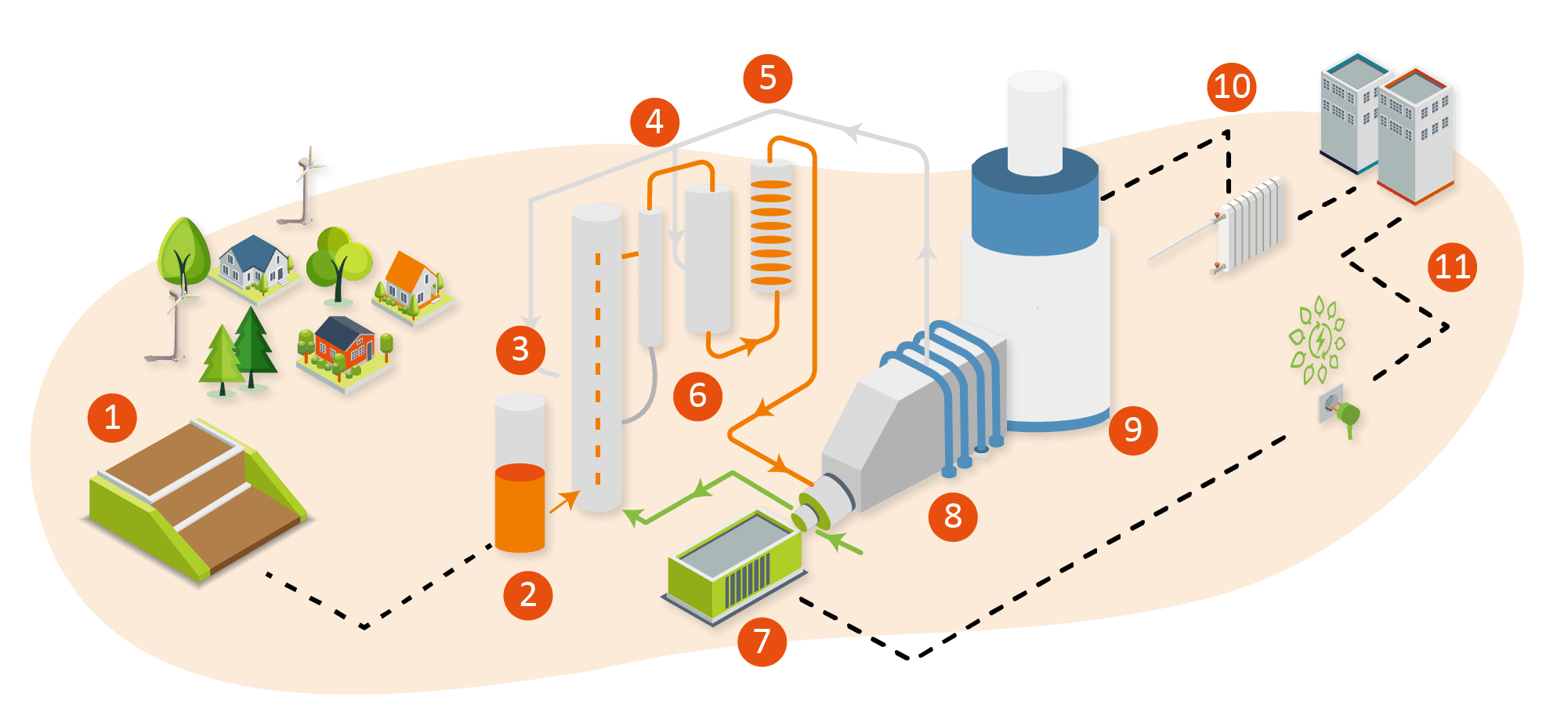

Bio-FlexGen scientists aim at increasing the flexibility of biomass-fired TopCycle (BTC) technology.

The underlying concept of the project is shown in the flowchart below. There are two main user types: district heating and industrial applications.

1 : Biomass

2 : Feeder

3 : Gasifier

4 : Gas cooler

5 : Hot gas filter

6 : Top Cycle gas turbine

7 : Generator

8 : Heat recovery steam generator

9 : Flue gas condenser

10 : Heat

11 : Electricity

The BTC plant

The BTC process is a highly-efficient CHP technology for medium-and large-scale plants (10-300Mw) with an electrical efficiency over 50 % and a total plant efficiency up to 110 %. Bio-FlexGen engineers will achieve this by using a hybrid air-blown gasification system to produce a syngas (mainly composed of N2, CH4, C0, C02, an H2). This is followed by combustion of the syngas in a Top Cycle gas turbine which drives a power generator. This enables the BTC process to generate two products: electricity AND heat, but with a much higher electrical efficiency than common steam cycles. This will decrease the levelised electricity costs from bioenergy CHP plants to 10-30% lower than fossil fuel plants (30€/ton C02). Furthermore, it produces up to three times more renewable electricity per heat sink than conventional bioenergy CHP and up to half the levelised costs.

The key elements of the BTC technology

- High-pressure hybrid FB gasification system (see item 3 in flowchart above)

- The steam-injected Top Cycle gas turbine (item 6)

- Heat integration

Background information on BTC:

The BTC technology has been developed by PHOENIX Biopower and associated companies during the last 10 years with funding from various projects and has achieved TRL 3. This technology is based on the following: a fixed configuration of a high-pressure (up to 45 bar) air-blown pressurised hybrid fluidised bed (HFB) gasification step. It is followed by a fixed configuration of syngas combustion in a steam-injected gas turbine – optimised for forest residues feedstocks.

The Bio-FlexGen approach: More flexibility

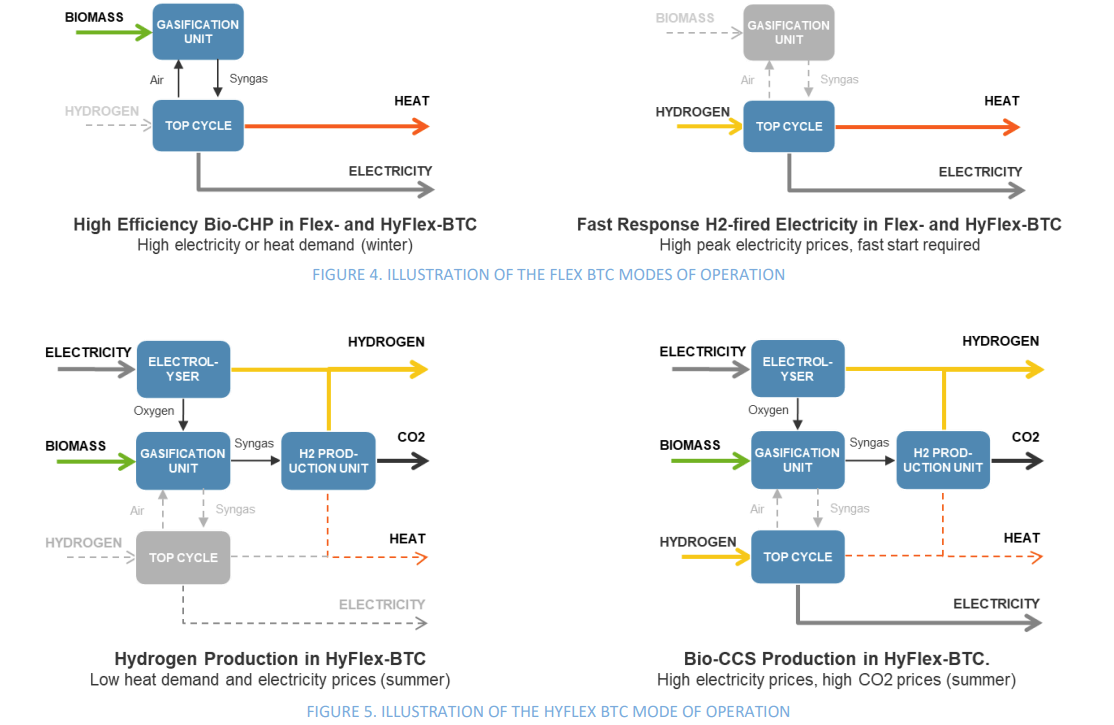

The first variant is called a Flex-BTC plant: A Bio-CHP with fast-start capability on hydrogen. The second configuration is more advanced. It is called HyFlex-BTC plant. It has both fast-starting and hydrogen-production capability. See figures 4 and 5 for the modi operandi. They introduce hourly, daily, monthly and seasonal flexibility into the Bio-FlexGen plant in different ways. The result: Stability in pricing and energy fluctuation in short and long term.

Four operation modes

- Bio-CHP mode: generation of low-cost electricity and heat from different biomass (load flex, daily/monthly flex)

- Fast response mode: generation of fast-response electricity from VRE-based H2 in the grid (hourly dispatch)

- Hydrogen production mode: hydrogen, heat and biogenic CO2 from biomass and VRE-based O2 (seasonal flex)

- Bio-CCS mode: power generation, via own-produced hydrogen, heat and biogenic CO2 from biomass (seasonal flex).

The result:

Bio-FlexGen can provide fast-dispatch for hourly/daily variable demand. And it adapts to seasonal (summer/winter) variable demand and fuel supplies for the energy system and/or (energy intensive) industries.

To reach this goal, Bio-FlexGen will develop and validate a hybrid gasification system. It can use various biomass waste streams in both air-blown and oxygen-blown modes. Therefore, either biopower or hydrogen production can be fed from the same reactor. The combustion chamber of the gas turbine will be designed and developed to operate with two very different fuels across gas turbine load: It will be able to switch between fuels at 30% load, in particular bio-syngas, coming from the biomass gasification process; and renewable hydrogen, coming from either electrolysers with wind/and or solar sources, or produced on-site from biomass.

Use Cases:

To optimise and validate the flexible operation modes, Bio-FlexGen will perform three use cases:

- District heating in Sweden

- Cement industry (CEMEX) in Spain

- Mining & chemical industry (SULQUISA) in Spain